Effective Solutions for Industrial Wastewater Management

- palwinder kaur

- Aug 30, 2025

- 3 min read

Industrial processes generate significant volumes of wastewater containing various pollutants. Managing this wastewater effectively is crucial to protect the environment, comply with regulations, and promote sustainable industrial growth. This article explores practical and effective industrial water treatment solutions that industries can implement to treat and manage their wastewater efficiently.

Understanding Industrial Water Treatment Solutions

Industrial water treatment solutions encompass a range of technologies and methods designed to remove contaminants from wastewater generated by manufacturing, processing, and other industrial activities. These solutions aim to reduce pollutants such as heavy metals, organic compounds, suspended solids, and toxic chemicals to safe levels before discharge or reuse.

Key Components of Industrial Water Treatment

Pre-treatment: Removal of large solids and grit to protect downstream equipment.

Primary treatment: Sedimentation and flotation to separate suspended solids.

Secondary treatment: Biological processes to degrade organic matter.

Tertiary treatment: Advanced filtration and chemical treatment to remove residual contaminants.

Sludge management: Safe handling and disposal of solid waste generated during treatment.

Each stage plays a vital role in ensuring the treated water meets environmental standards and can be safely discharged or reused within the facility.

Advanced Technologies in Industrial Water Treatment Solutions

Modern industries increasingly adopt advanced technologies to enhance the efficiency and effectiveness of wastewater treatment. These technologies not only improve pollutant removal but also reduce operational costs and environmental impact.

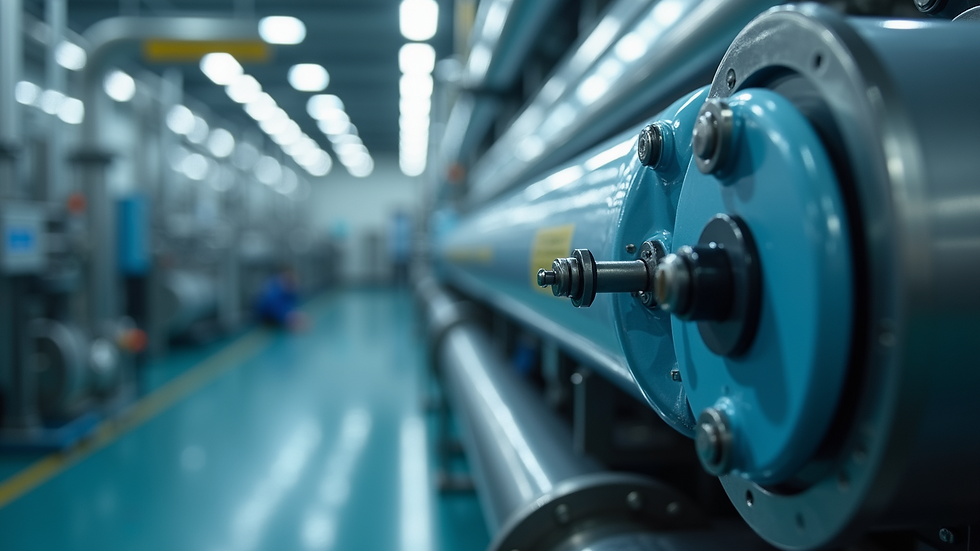

Membrane Filtration

Membrane technologies such as ultrafiltration, nanofiltration, and reverse osmosis provide high-quality water by physically separating contaminants at a molecular level. These systems are compact, energy-efficient, and capable of removing dissolved solids, bacteria, and viruses.

Biological Treatment

Biological treatment uses microorganisms to break down organic pollutants. Common methods include activated sludge processes, biofilm reactors, and anaerobic digestion. These methods are cost-effective and suitable for treating biodegradable waste.

Chemical Treatment

Chemical processes such as coagulation, flocculation, and oxidation help remove heavy metals, color, and toxic substances. These treatments are often combined with physical and biological methods for comprehensive wastewater purification.

Zero Liquid Discharge (ZLD)

ZLD systems aim to eliminate liquid waste by recovering and recycling all water from the wastewater stream. This approach minimizes environmental discharge and maximizes water reuse, making it ideal for water-scarce regions.

Practical Steps to Implement Industrial Water Treatment Solutions

Implementing effective industrial water treatment requires a systematic approach tailored to the specific wastewater characteristics and regulatory requirements.

1. Conduct a Wastewater Audit

Analyze the volume, composition, and variability of wastewater generated. Identify key pollutants and their concentrations to select appropriate treatment technologies.

2. Design a Customized Treatment System

Based on the audit, design a treatment system combining physical, chemical, and biological processes. Consider factors such as space availability, budget, and future scalability.

3. Install Monitoring and Control Systems

Automated sensors and control units help maintain optimal treatment conditions, detect anomalies, and ensure compliance with discharge standards.

4. Train Personnel

Equip staff with knowledge and skills to operate and maintain treatment systems effectively. Regular training improves system reliability and reduces downtime.

5. Explore Water Reuse Opportunities

Treated water can be reused for cooling, cleaning, or irrigation, reducing freshwater consumption and operational costs.

Benefits of Effective Industrial Wastewater Management

Adopting robust industrial water treatment solutions offers multiple benefits:

Environmental Protection: Reduces pollution and protects aquatic ecosystems.

Regulatory Compliance: Meets legal discharge standards, avoiding fines and shutdowns.

Resource Conservation: Enables water reuse, reducing freshwater demand.

Cost Savings: Lowers wastewater disposal costs and potential penalties.

Corporate Responsibility: Enhances company reputation and stakeholder trust.

Industries committed to sustainable practices gain a competitive edge and contribute positively to community health and environmental stewardship.

Future Trends in Industrial Water Treatment

The future of industrial water treatment is shaped by innovation and sustainability goals. Emerging trends include:

Smart Water Management: Integration of IoT and AI for real-time monitoring and predictive maintenance.

Green Treatment Technologies: Use of natural processes and eco-friendly chemicals.

Circular Economy Models: Emphasis on water reuse and recovery of valuable by-products.

Decentralized Treatment Systems: Modular and mobile units for flexible wastewater management.

Staying abreast of these trends helps industries optimize their wastewater treatment strategies and align with global sustainability targets.

For industries seeking reliable and efficient solutions, exploring industrial wastewater management options is essential to achieve environmental compliance and operational excellence. Implementing the right combination of technologies and practices ensures sustainable water use and long-term business success.

Comments