Effective Strategies for Managing Industrial Wastewater in India

- palwinder kaur

- Aug 7, 2025

- 4 min read

Industrial effluent treatment is a critical concern in India due to the rapid growth of industries and the increasing demand for sustainable environmental practices. Managing wastewater generated from industrial processes is essential to protect water bodies, public health, and comply with environmental regulations. This article explores effective strategies for industrial effluent treatment, focusing on practical solutions and technologies that industries in India can adopt to manage their wastewater efficiently.

Understanding Industrial Effluent Treatment in India

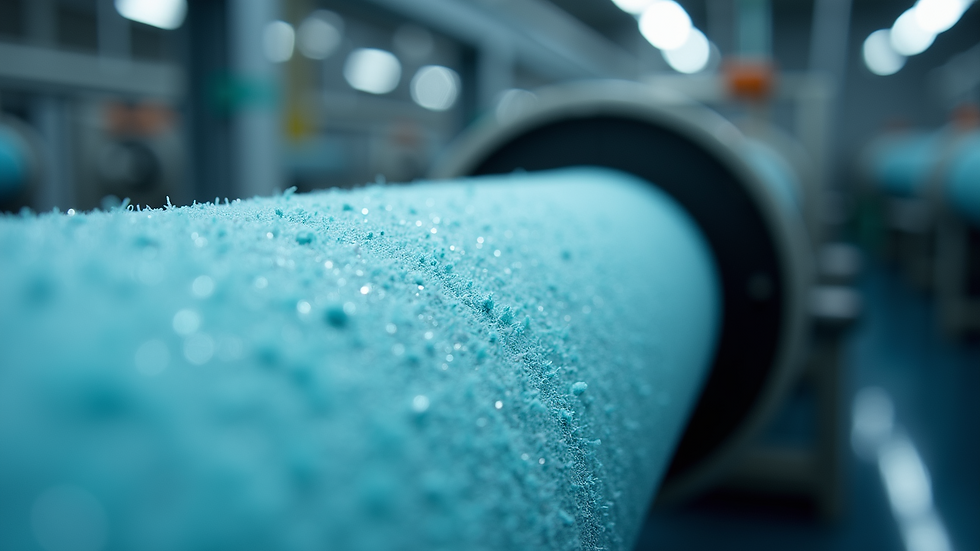

Industrial effluent refers to the wastewater discharged from manufacturing or processing plants. This wastewater often contains harmful chemicals, heavy metals, and organic pollutants that can severely impact the environment if not treated properly. In India, industries such as textiles, chemicals, pharmaceuticals, and food processing generate large volumes of effluent that require specialized treatment methods.

The government has set strict regulations under the Water (Prevention and Control of Pollution) Act, 1974, and the Environment Protection Act, 1986, to ensure industries treat their wastewater before discharge. Compliance with these regulations not only helps in environmental conservation but also avoids penalties and legal issues.

Key Challenges in Industrial Effluent Treatment

High pollutant load: Industrial effluents often contain complex pollutants that are difficult to treat.

Resource constraints: Many small and medium enterprises (SMEs) lack the financial and technical resources for advanced treatment systems.

Lack of awareness: Some industries are unaware of the latest treatment technologies and best practices.

Infrastructure limitations: Inadequate infrastructure for effluent collection and treatment in industrial clusters.

Advanced Technologies for Industrial Effluent Treatment

To address the challenges of industrial effluent treatment, industries in India are increasingly adopting advanced technologies that improve treatment efficiency and reduce environmental impact. Some of the most effective technologies include:

1. Physical Treatment Methods

Physical methods involve the removal of suspended solids and floating materials through processes such as sedimentation, filtration, and flotation. These methods are often the first step in effluent treatment.

Sedimentation tanks: Allow heavy particles to settle at the bottom.

Screening: Removes large debris and solids.

Filtration: Uses sand or membrane filters to remove finer particles.

2. Chemical Treatment Methods

Chemical treatments involve adding chemicals to neutralize or precipitate pollutants.

Coagulation and flocculation: Chemicals like alum or ferric chloride are added to aggregate suspended particles.

pH adjustment: Neutralizing acidic or alkaline wastewater to safe levels.

Oxidation: Using oxidizing agents to break down organic pollutants.

3. Biological Treatment Methods

Biological treatment uses microorganisms to degrade organic pollutants in wastewater.

Activated sludge process: Aerobic bacteria consume organic matter.

Anaerobic digestion: Microorganisms break down waste in the absence of oxygen, producing biogas.

Biofilters and bioreactors: Support microbial growth on surfaces to treat wastewater.

4. Membrane Technologies

Membrane filtration, such as reverse osmosis and ultrafiltration, provides high-quality effluent by removing dissolved solids and contaminants.

Reverse osmosis: Removes salts and small molecules.

Ultrafiltration: Filters out bacteria and suspended solids.

5. Zero Liquid Discharge (ZLD)

ZLD systems recycle all wastewater within the plant, leaving no liquid discharge. This method is gaining popularity in water-scarce regions of India.

What is Industrial Wastewater Treatment?

Industrial wastewater treatment is the process of removing contaminants from water used in industrial processes before it is released into the environment or reused. The goal is to reduce pollutants to acceptable levels to protect ecosystems and human health.

The treatment process typically involves several stages:

Preliminary treatment: Removal of large solids and grit.

Primary treatment: Sedimentation to remove suspended solids.

Secondary treatment: Biological processes to degrade organic matter.

Tertiary treatment: Advanced methods like filtration, disinfection, and chemical treatment to remove remaining pollutants.

Each industry may require a customized treatment approach depending on the type of effluent generated. For example, textile industries focus on removing dyes and chemicals, while pharmaceutical industries target organic compounds and heavy metals.

Importance of Industrial Wastewater Treatment

Environmental protection: Prevents contamination of rivers, lakes, and groundwater.

Resource conservation: Treated water can be reused, reducing freshwater demand.

Regulatory compliance: Meets legal standards to avoid fines and shutdowns.

Corporate responsibility: Enhances company reputation and sustainability credentials.

Practical Strategies for Effective Industrial Effluent Treatment

Implementing effective industrial effluent treatment requires a combination of technology, management practices, and regulatory compliance. Here are some actionable strategies:

1. Conduct Regular Wastewater Audits

Performing audits helps identify the sources and types of pollutants in the effluent. This information is crucial for designing an effective treatment system.

Map all wastewater generation points.

Analyze effluent characteristics regularly.

Identify opportunities for waste minimization.

2. Invest in Customized Treatment Solutions

No single treatment method fits all industries. Tailor solutions based on the effluent composition and volume.

Use modular treatment units for flexibility.

Combine physical, chemical, and biological methods.

Consider advanced technologies like membrane filtration for high purity.

3. Promote Water Recycling and Reuse

Reusing treated wastewater reduces freshwater consumption and lowers discharge volumes.

Use treated water for cooling, irrigation, or cleaning.

Implement ZLD systems where feasible.

Monitor water quality to ensure safe reuse.

4. Train Staff and Raise Awareness

Educate employees about the importance of wastewater treatment and proper handling of chemicals.

Conduct regular training sessions.

Develop standard operating procedures.

Encourage reporting of leaks or spills.

5. Collaborate with Technology Providers

Partnering with experts in industrial wastewater management can help industries access the latest technologies and best practices.

Seek consultancy for system design.

Use service providers for maintenance and monitoring.

Stay updated on regulatory changes and innovations.

Future Trends in Industrial Effluent Treatment in India

India's industrial sector is evolving rapidly, and so are the methods for managing effluent treatment. Some emerging trends include:

Digital monitoring: Use of IoT sensors and AI for real-time effluent quality monitoring.

Green technologies: Adoption of eco-friendly treatment methods like constructed wetlands.

Decentralized treatment: Small-scale treatment units for individual industries or clusters.

Policy incentives: Government subsidies and support for adopting advanced treatment systems.

By embracing these trends, industries can improve their environmental performance and contribute to sustainable development goals.

Moving Towards Sustainable Industrial Effluent Management

Effective industrial effluent treatment is not just a regulatory requirement but a vital step towards sustainable industrial growth in India. By adopting advanced technologies, optimizing processes, and fostering a culture of environmental responsibility, industries can significantly reduce their water footprint and pollution load.

Investing in efficient treatment systems and collaborating with experts in industrial wastewater management will ensure compliance, cost savings, and a healthier environment for future generations. The journey towards sustainable industrial effluent treatment is ongoing, and proactive measures today will pave the way for a cleaner, greener India tomorrow.

Comments